Choices facing technology decision-makers are becoming increasingly complex due to rapid changes in the industry like broadcast and IP technology convergence, multiplatform demands, and the rise of 4K and 8K. It is now a constant challenge to balance the need to maintain already-installed equipment and fulfil the desire to provide the highest resolution picture and sound.

This challenge is no more evident than in the Outside Broadcast (OB) market. OB firms have been operating in an increasingly competitive environment and are now hampered by ambiguity around which technology should be adopted, and when it should be rolled out. Engineers constantly have to breathe new life into legacy equipment that was originally designed to handle HD-SDI but must now become 4K- or 8K-capable. Fortunately, the industry\'s supply chain is also evolving by becoming more service-oriented. For a distributor like Argosy, that has meant undergoing a variety of organizational shifts that have enabled us to accommodate the increasingly unique nature of each project.

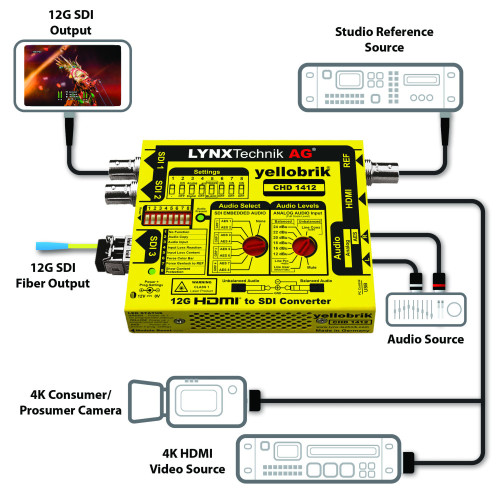

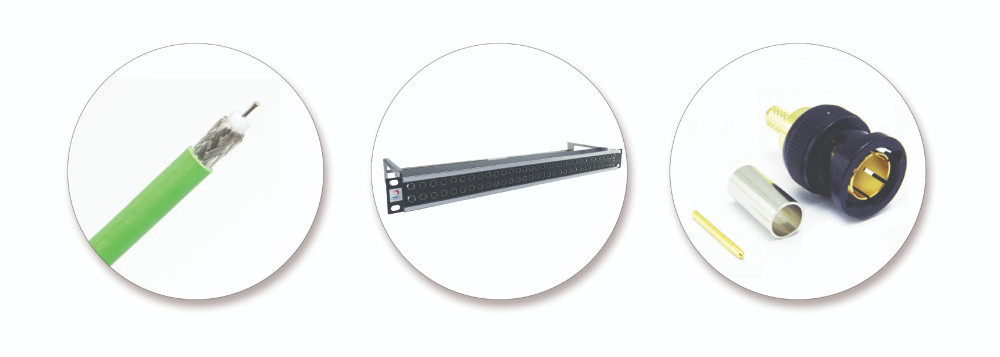

The most modest of these shifts was a renewed focus on consultative selling. There are plenty of options that many broadcasters just aren\'t aware of when it comes to balancing quality and cost. For example, fibre is usually the go-to cable type when upgrading to 4K. In the OB realm this applies to critical signals running to and from mobile production vehicles at live sporting events. However, standard coax is actually adequate for 4K signals over shorter cable runs -- across rack-rooms, for example.

In the case of an OB truck with coaxial cable inside, the run lengths will be relatively short, meaning legacy equipment can be used and complemented with 4K hardware. So, instead of throwing out the existing equipment and starting again at great cost, suppliers are focused on providing engineers some insight and guidance on what the existing coaxial solution is capable of: Does it need replacing? Do certain lengths need to be re-run? What cable options are available?

A recent solution we employed for OB vehicles was advocating for installation of the Image 360 cable, a lighter and thinner product than the traditionally used Image 2000. This alternative solution will handle 4K within a truck, while taking up less room in the cable tray and inside the racks, and at a much lower cost. A simple cable replacement improved the ease of install and decreased the customer\'s procurement and operating costs.

Many suppliers have also sought to improve their ability to react to unique operational needs. For example, OB companies are constantly seeking new ways to reduce rigging and de-rigging times at events. Collaborating with a client led to the development of a deployable case assembly. This pre-terminated cable maintains high signal quality but brings additional value by reducing labour time onsite, one of the largest costs of an install project.

Perhaps these changes are representative of those in the middle of the chain shifting their focus from simply delivering products to delivering business solutions. One pain point for OB operators is the propensity to return from an event with damaged cables. In theory, this is a great problem for a supplier. But, it impacts the customer\'s profitability, and therefore the supplier\'s long-term outlook as well. In response, we launched cleaning and repair services for damaged cables, seeking to maximise their life-cycle. While not as immediately gainful as the sale of a new cable, it prevents clients from having to renew their stock at greater cost and demonstrates supplier commitment to providing commercially sound support. Again, a solution for the outside broadcaster\'s ROI, not just product delivery.

To support this shift in focus, it\'s important that a cable supplier invests in additional infrastructure to meet these ongoing demands. We invested in a fibre termination facility with a clean room, fibre connectivity, and a splicing and polishing machine to enable the termination of multi-way fibres. An assembly department also develops, builds, and tests products to ensure they reach certain distances, with test and measurement equipment to validate signals on various type of equipment, fostering our ability to consult with our broadcast customers.

Cabling is now an area where OBs are actively approaching suppliers for help in maximising existing investments. This has presented an opportunity to reinforce the value experts bring in a particular field (like cabling), transforming companies like Argosy from pure product shifters into service providers.