The greening of broadcast facilities

Author: Chris Excelby

Published 1st July 2013

By Chris Exelby, Managing Director, TSL Professional Products, Ltd.

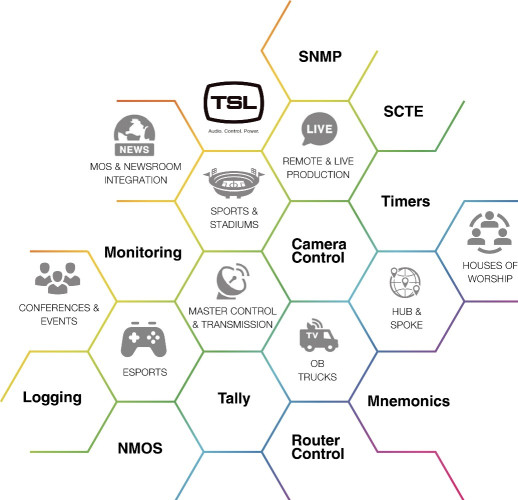

In today’s world of tightening broadcast facility budgets, planners need to keep a keen eye on the bottom line to ensure operational efficiency. An integral part of this process is getting a green handle on power management, an increasing necessity around the globe. Power management not only helps with awareness of system components, concerning signal integrity and maintenance, but also for conserving power to meet Power Usage Effectiveness (PUE) goals needed for green credentials.

An important factor in power management is the ability to intelligently monitor the operational environment very quickly and pass this information to the maintenance engineers instantly. An alarm is often the first warning an engineering team will get that something is broken. The feedback provided by the alarm, depending on the power solution, includes information about temperature, current and voltage going to each individual rack-mounted unit in a facility. As there are many different types of alarms available, the engineering team can use this information to quickly assess the problem, locate the offending gear and institute a fix. This allows the broadcaster to identify faults more quickly, thereby streamlining facility quality assurance.

Ethernet connectivity and IP-capable monitoring of studio equipment, is a second element to look for in power management, as a chief engineer can then monitor racks of equipment wherever they are situated, either locally or in facilities around the world. This centralized approach means a broadcaster can keep the engineering management in one location, and this engineering team can then issue orders out to the maintenance engineer on site. This allows a broadcaster to rely on fewer engineers in general, and those engineers can be deployed more efficiently to maintain operational integrity.

Power management helps green capabilities to be realized through the efficient use of equipment. This engineering direction came to light for TSL through a conversation with a broadcaster in India. Certain locations in India have particular problems with the generation and wasting of power, including brownouts and mandatory usage reductions. This particularly impacts a broadcast facility where the equipment in the racks is usually powered up all the time. Most equipment has an on/off switch on the back of the unit, which is, therefore, inaccessible to the staff. So even if there was the desire to turn off equipment at night when the station is playing out programs that were pre-recorded, jumping into the back of the equipment racks is extremely impractical, if not impossible. Additionally, manually turning equipment off overnight and then turning it on again in the morning opens up a Pandora’s Box of possible problems and oversights. When the inevitable happens and a key piece of gear is left off right before a live presentation, the mad scramble begins.

The TSL engineering team took this question to heart and implemented a software solution for its power management products where the user can specify rack by rack and location to location what equipment is not necessary for overnight operations, as an example. The last person out the door can select the ‘Out-of-Hours’ working preset created by the facility engineering team, locally or remotely, and the system will automatically go through the entire network and switch everything off that isn’t required for continued station operation. This solution allows businesses to meet PUE goals that help demonstrate the demanding ‘green’ capabilities for ‘green’ credentials. Our Indian customer estimates that by using this method of power management, they will be able to save 40 percent of their power bill, which is quite significant for the operational bottom line. In a broadcasting world looking for cost saving efficiencies, this solution is the obvious first step for green-inspired cost cutting.

And of course this particular application in India gets even more complex because the power company will often call and say, ‘you’ve got to cut your power consumption by 20 percent for two hours’, or ‘60 percent between 5:00 and 10:00 PM.’ For example, if one recurring power reduction request is normally 20 percent, the station can implement a preset and close down the equipment in, say, studios three and four because during that time those studios are not active. If a recurring request comes in for a 60 percent reduction, the station can determine the least amount of equipment needed across the entire facility to keep programming going. The TSL system allows the station team to make these decisions before there is a crisis request and appropriately react to meet the situation while continuing the broadcast schedule. The implications for broadcasters around the world is that emergency operational protocols for whatever reason can now be programmed in as a preemptive move for continued broadcast.

The engineering team at TSL PPL has refined its power management family of Power Distribution Units (PDU) to fully address the needs of this global trend through intelligent power distribution, management and control to realize green benefits. The TSL PPL MDU-12PMi 16 amp and MDU-12PMi-32A 32 amp rack-mount units provide complete visibility of the health of the rack, monitoring status and alerting if pre-set limits are exceeded, as discussed above. It also offers 12 individually switched outlets with current, power and power factor measured both individually for each outlet and collectively in total. To meet the criteria for remote monitoring of system assets, programmable alerts, communicated via E-mail, SMS (via external gateway) and SNMP traps, have been engineered into the systems. Alerts include failed fuses, 16 GPI inputs, temperature sensor, or over and under current consumption by outlet. To realize the green benefits, MDU-12PMi/PMi-32A units have been engineered to offer the opportunity to invoke system pre-programmed power maps using the TSL management software PsiMon, over LAN or WAN for energy management or individual equipment control.

These units are designed to sit at the front of an equipment rack. The VIP series offers all of the above features, but is designed to mount vertically on the rear of an equipment rack to facilitate AC wiring. The engineering team can use the supplied power chords for each piece of rack-mount gear without modification because the power outlets run vertically and remain in close proximity to each power chord.

In a world that experiences increased demands from power utilities year in and year out, combined with the need for green consciousness and certification, effectively managing power consumption to yield cost saving efficiencies is the order of the day. TSL PPL has met this challenge by designing power management products that are rugged, highly reliable and aggressively priced. With TSL, the greening of the broadcast industry is in good hands through its PDU power management approach.